TRIFORCE® makes your work on the jobsite easier. It offers many features that can help you get your jobs done quicker, reduce overall construction costs and make it easy for your framers to use. Learn all about the TRIFORCE® features and benefits in this section of the blog.

We all know the pace of business is speeding up and our goal is often to check something off our to-do lists because time is money and delay can be really pricy. There is a cost to added time and the cost of that delay can easily exceed the savings from low-cost products. All-wood Finger-joined … Continued

You probably already know you can have access really rapidly to the TRIFORCE® because it is always in stock. But what makes it so different from other regular wood I-joists? The mix of an open web design and trimmable end First, let’s discover how the TRIFORCE®’s open web design can help you lower your costs.TRIFORCE® … Continued

In recent blog articles, we could observe many builders using and recommending TRIFORCE® joists for single-family residential construction and multi-family projects. Well there is a third category of buildings where TRIFORCE® has proven to be very successful: light commercial construction. Successful floor systems for commercial applications Whether it is for a restaurant, a bank, a … Continued

Can an open web joist that is a rising star in residential floor framing fill the bill for Multi-Family floor assemblies? The answer to our question is a BIG YES! TRIFORCE® open joist will meet or surpass your floor framing requirements of Multi-Family housing. It will provide you with a solid feeling floor system, fire … Continued

Builders have guts. They have the courage to assemble products and build homes from scratch with their own hands. They are visionaries who transform empty lots into beautiful and exciting living spaces. They do this in the face of adversity, tight budgets, short deadlines, workforce shortages, and countless other challenges playing against the timely completion … Continued

TRIFORCE® experts are regularly invited as speakers for continuing education webinars. One participant recently asked if open web floor joists still require rim board. I thought that was an interesting question because once you understand everything rim board does, you adopt it. Rim board: An essential part of an engineered wood floor system Rim board … Continued

Used for centuries in many different ways, cantilevers as a construction device were first recognized in 19th Century bridge designs. But they gained significant notice in architectural use when Frank Lloyd Wright unveiled his iconic “Fallingwater” commissioned residence. There the cantilever was not just a structural means to an end but also a dramatic design … Continued

1) Joist Repair Needed Recently, a TRIFORCE® representative was called to a construction site because the GC had discovered a cracked bottom chord on one of the installed TRIFORCE® joists (see photo above). The cause of the damage was a mystery and no one was taking responsibility. What could have happened? First… we know what … Continued

In North America residential construction, wood has long been a material of choice: abundant, readily available, flexible, and easily repairable, it is less expensive than steel and concrete, and is naturally an overwhelmingly popular material. For some 40 years now, engineers and builders have had the choice between using traditional lumber or engineered wood for … Continued

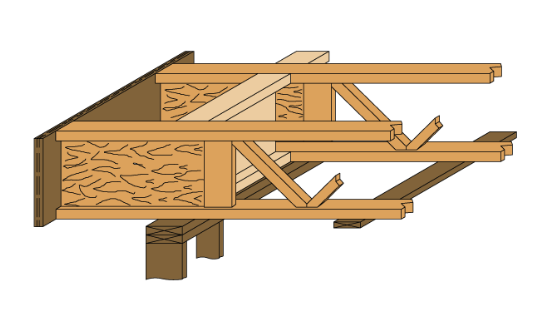

While floor systems have evolved through time, the good ol’ floor truss is still around. Admittedly, it does have certain advantages. But how does it compare to the latest generation of our floor solution: TRIFORCE® open joist? Floor truss characteristics Floor trusses are certainly a viable option for your floor structure. A floor truss consists … Continued