TRIFORCE® makes your work on the jobsite easier. It offers many features that can help you get your jobs done quicker, reduce overall construction costs and make it easy for your framers to use. Learn all about the TRIFORCE® features and benefits in this section of the blog.

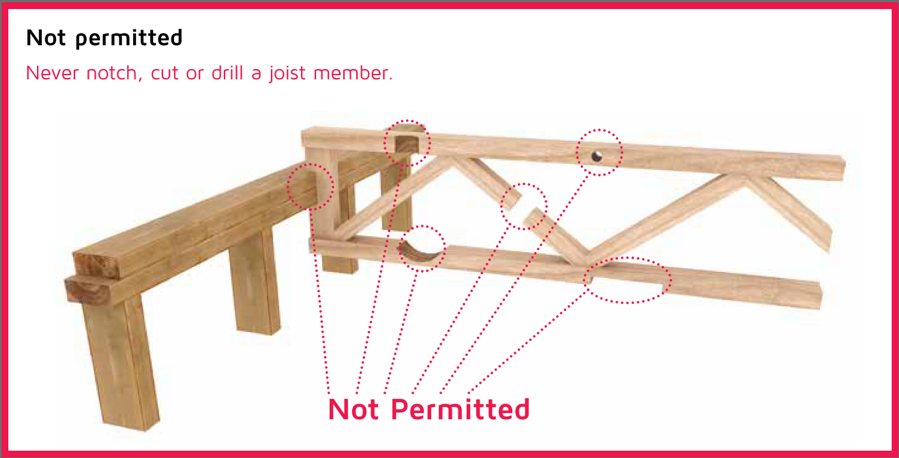

You’re a builder visiting your jobsite the day after the trades have finished their installations, and you immediately realize something is wrong. The brand new joists you carefully installed have been cut, drilled or otherwise mangled! Welcome To Your Worst Nightmare! Plumbers, electricians and HVAC contractors have left their marks, altering your floor system so … Continued

Today’s housing market offers an ever-increasing variety of construction materials. From the more traditional lumber that we’ve been using for centuries, the industry moved to more efficient solutions. The I-joists and plated trusses appeared in the late 60’s and early 70’s to challenge widespread methods and standards. But it wouldn’t be until 1990 that a … Continued

“Why should I use a floor joist that is trimmable when I can install a made-to-length truss immediately?” Because it’s not a perfect world! Just ask the framer who, after finishing his morning coffee, opens the bundle of trusses, hoists the first one onto the foundation and discovers it’s too short by 6 inches. Ask … Continued

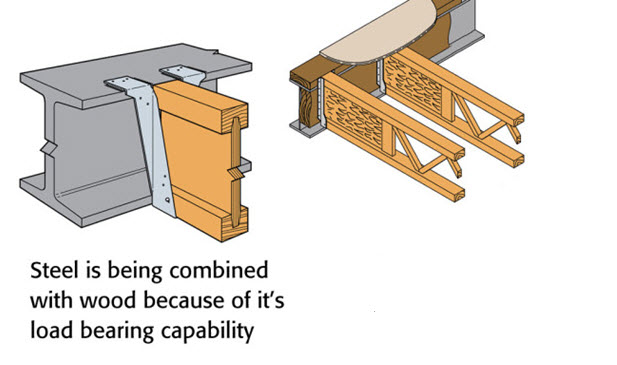

It’s not enough to simply specify the right components for a building project. An architect, engineer or designer must also specify how those components should be installed… how the pieces connect to one another. Sometimes a simple fastener schedule is adequate when wood-to-wood connections are needed. But often, especially in today’s world of engineered building … Continued

When designing a floor system, it is crucial to understand how weight and loads are distributed throughout a building. Often, floor framing plays an important role in transferring loads from the roof to the foundation of a building. To ensure proper structural integrity, the floor loading assessment must account for factors such as roof design, … Continued

The Passive House movement is becoming a growing trend in the construction industry. Indeed, the idea of building the most energy efficient house has finally become a reality, and the movement is increasingly inspiring builders to improve their projects. The Passive House concept has achieved a certain notoriety in Europe. It actually comes from Germany, … Continued

Contrary to floors built with 2″ x 10″, an engineered wood floor system allows you to hide a large portion of a house’s mechanical systems. Using the floor cavity in this way enables you to design uniform, wide open living spaces. It also reduces the need to run HVAC ducting in attic spaces, which from … Continued

Every once in a while we like to get back to basics with some installation tips. If you are new to installing TRIFORCE®, these guidelines will help you transition from what you were using before. For those of you that are already using this great product, there’s no harm in going over a quick refresher in … Continued

Customers regularly ask me if they can cut strongbacks. The short answer is yes, but before explaining how, here’s a quick rundown of what strongbacks are, for those of you who aren’t familiar with them. What strongbacks are Strongbacks are horizontal members that attach perpendicularly to a series of open web joists, inside the floor cavity. Their purpose is … Continued

An open web design has many advantages over I-joists or 2″ x 10″ when it comes to humidity control during building closure and utility installation. Humidity control to avoid problems down the road Proper temperature and humidity control during and after the building’s transition to being closed are essential. High humidity levels, heavy rain or snowmelt … Continued