Customers regularly ask me if they can cut strongbacks. The short answer is yes, but before explaining how, here’s a quick rundown of what strongbacks are, for those of you who aren’t familiar with them.

What strongbacks are

Strongbacks are horizontal members that attach perpendicularly to a series of open web joists, inside the floor cavity. Their purpose is to reduce vibration while increasing floor comfort and performance. During construction, they also prevent joist rollover. Depending on the floor dimensions, they can consist of 2 x 4, 2 x 6 or 2 x 8. See our spec guide for prescribed sizes.

If you are using I-joists, strongbacks are like blocking, the segments of I-joist, rim board or other engineered wood are cut and installed between joists. Installing strongbacks within an open web floor system, however, is much easier than that. Have a look at this short video

What strongbacks are not

Strongbacks aren’t structural elements and aren’t load bearing, nor are they required by the IRC or the IBC.

Advantages

If the designer is concerned about floor performance and occupant comfort, strongbacks are much easier and cheaper to install than blocking or X-bridging. That’s why we always recommend adding them.

Yes, you can cut strongbacks

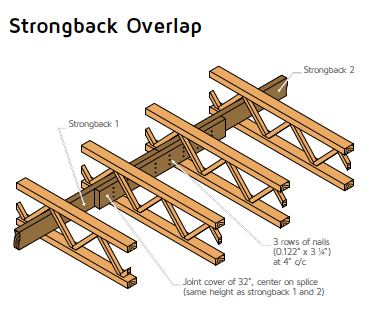

Ok, back to the question. Strongbacks interconnect joists to share vibration amongst floor members, so ideally, they run across a maximum number of joists. If you need a pathway across the strongback for an HVAC or plumbing run, you can cut the strongback, making sure that no less than 3 joists are connected per strongback segment.

If needed, you can attach an additional segment to the strongback by overlapping it, such as illustrated here

Strongbacks can also be staggered across the floor system, down the entire length of the floor if needed.

Finally, remember that is is much easier to install strongbacks before applying the floor membrane.

By the way, we just launched a whole series of videos illustrating the benefits of using an open web system like TRIFORCE®. If you are interested, have a look at them.

In addition to your note

“Finally, remember that is is much easier to install strongbacks before applying the floor membrane.” I would suggest you add advisement to also pre-place sufficient number of strongback components into the required bay(s) prior to either, setting all of the joists, or placement of the trimmer rim boards. (so you have end access to slide the best and longest 2x strongback members loosely into place.

I did not check the current installation manuals before writing this – probably already stated there … if not – worthy to add.

I have bee employing / specifying OJ’s since they first came to market and have had a longstanding good relationship with your flag-ship Ottawa operation (Paul Byrne etal) from early on in the Superior truss days too.

Great system … though I spoke to OJ corporate engineering before the new OJ-Tri-Force was launched, and noted that the use of the OSB sheet in lieu of say ‘fire rated’ plywood would be an ‘Achilles Heel’ since OSB ‘vaporizes’ quickly in a fire.

At the time I also sent Paul pics of OSB / Wood-I vs OJ-2000 post-fire damage shots from some local fires to really illustrate this. I can send them to you as well, if of interest to your group.

Just e-mail me.

Don Brown, B.Arch., BCIN, Brown Custom Design, Ottawa

Can strong back be laid flat on its face ?

Hello Brandon,

Strongbacks are only effective if installed properly. They are positioned on edge on the joist’s bottom chord and run continuously through the floor framing cavity.

For more details about strongback, please refer to this aticle: “ADVANTAGES FOR BUILDERS TO INSTALL STRONGBACKS IN AN OPEN WEB FLOOR SYSTEM“.

Best regards

The TRIFORCE team

I have a situation where I need to move two strongbacks up about 3 1/2 inches. They are in an open web truss under the kitchen floor. It’s a 16ft x 16ft room in the basement. Can I move them up and then add X bracing?

I am doing a studio build which will be a decoupled room inside a room. My new ceiling joist will set in between the existing open web truss in order to have ceiling hight I need for the studio and the strongbacks now are in my way.

Thanks

Hello Joe and thank you for your question,

As a matter of fact, yes you can move those strongbacks up into the floor system.

Please use a vertical side block (2×4) to help you fix your strongbacks as per our detail N5 (better):

You won’t need other material like x-bracing if the strongbacks installed are of the recommended size.

Do not hesitate to contact our technical team at 1-800-263-7265.

Hey. I’m running new hvac duct in a open web truss floor system. There has already been duct work added 20 years ago but I need to update the system. There is a 10’ 2×6 strong back that has been cut during initial building in its center ,leaving two 5’ sections . I need to cut one of the 5’ sections to allow more ducting. That 5’ Piece is located in the middle part of the room Is that ok to do?

Hello Paul,

A strongback should be as continuous as possible and installed as close as possible to mid-span.

That being said, when considering a TRIFORCE® floor system, and if you need a pathway across the strongback for an HVAC or plumbing run, you can cut the strongback, while making sure that no less than 3 TRIFORCE® joists are connected per strongback segment.

Do not hesitate to contact our TRIFORCE® technical team at 1-800-263-7265 for support related to your specific project.

We have option 2 for our stongback installation however because of ductwork it is not continuous. Is it possible to attach a 2×4 above the ductwork, nail it to the vertical side block and overlap it as suggested in the strongback overlap.

Hello Mary Ann,

Yes, you can locally add another strongback over your ductwork using the “better” method with side block. Always make sure to secure your strongback to as least 3 consecutive joists.

For the other strongbacks to be installed in your floor system, we encourage you to fixed those through bottom chord. Do not hesitate to contact our TRIFORCE® technical team at 1-800-263-7265 for support related to your specific project.

Thanks for following us on our blog!

Caroline

We are limited on where strongbacks can be installed due to windows in the basement. Can strongbacks be installed too close together? Can you do more harm if not properly spaced?

Thanks

Hello Chuck and thank you for your inquiry!

If your plans (or joist placement guide) call for two strongbacks we recommend installing them side-by-side as close to the midspan of the joist as possible.

Please also reference Detail 5 on page 20 of our U.S. Specifier Guide.

Thanks for using TRIFORCE joist!