It may be common thinking to describe a floor only as a series of joists with secure floor sheathing on top of them. But, for it to be an effective floor system, there’s more to it than that. At TRIFORCE®, we aim to create floor systems that surpass industry standards, providing strength, durability, and comfort. Here are 4 main elements in the TRIFORCE® floor system assembly.

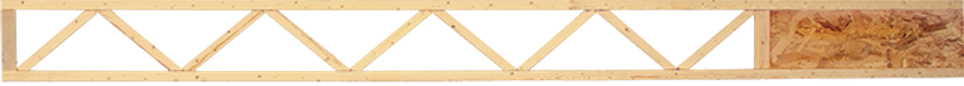

1) The joist

A quality floor system starts with a joist that is built to the latest standards for stiffness and shear resistance. Open joist TRIFORCE®, for example, complies with ASTM D5055 criteria.

To be effective, a joist should also be trimmable. Measurement errors happen and a jobsite shouldn’t grind to a halt while waiting on replacement trusses, and engineering approvals. The open joist TRIFORCE® has a trimmable end which is cut up to 24”.

TRIFORCE’s open web design will also help speed up plumbing, electrical and HVAC installation. If you have to cut holes into your joists after installing them, you are wasting time and exposing yourself to possible repairs for mis-placed holes.

The TRIFORCE® joists are all-wood components with finger jointed web connections. Since there are no metal plate connectors, TRIFORCE® open joists have a better fire resistance, and are lighter in weight which makes them easier to handle. Additionally, there is no risk of injuries to workers from the sharp metal edges and no damage to wires, pipes and ductwork.

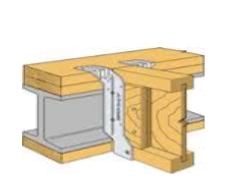

2) The proper hangers

Choice of the appropriate hangers when building a floor will make a significant difference in the quality of the structure. Most structural failures occur at connection points. Bending and nailing a connector into place is asking for trouble. Always use the recommended hanger to ensure a snug and secure fit.

It’s also possible to fix a perpendicular joist to a steel I beam with hangers. Most frequently, the top of the I-beam is capped with a wood plate to which top-mount joist hangers can be nailed. This wood to steel connection is represented in the image below:

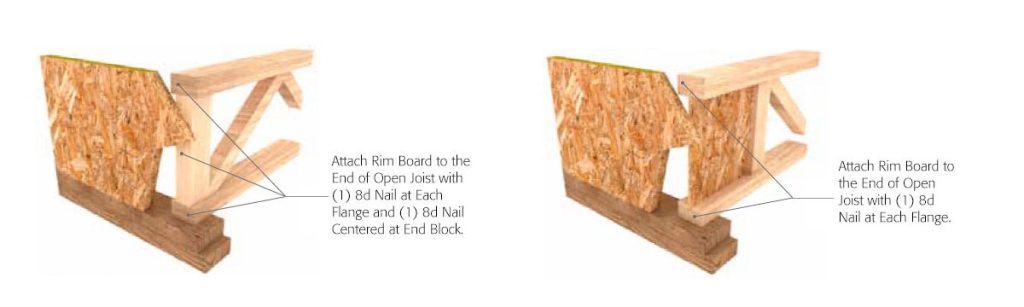

3) EWP rimboard

We also recommend the use of structural rimboard when installing TRIFORCE®, because of its ability to transfer load between levels of the structure. Rim board sits on the sill plate and forms a band around the perimeter of an engineered wood floor system, matching the full depth of the joists. It carries axial and lateral loads coming from the exterior walls. It also strengthens the floor structures resistance to shear loads, whether they are coming from the floor sheathing, inside walls or exterior forces such as wind.

EWP rim board should be used to ensure the assembly’s quality and dimensional consistency.

Installation is simple :

EWP rim board is an essential element for your project that will ensure maximum quality for your floor structure. Connecting the rimboard to the joists provides lateral support to the joists and resistance against rotation.

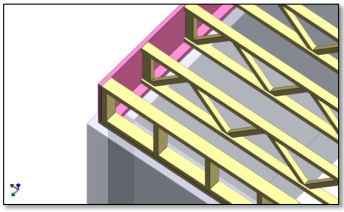

4) Strongbacks

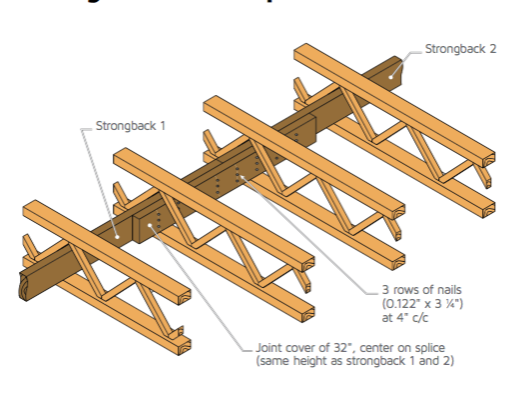

The use of an open joist design enables you to improve floor assembly performance with strongbacks. This inexpensive and easy to install transversal member enhances the joists’ capacity to reduce vibration and increase the perceived quality or “comfort” of the floor.

If you are using an open-joist floor system, strongbacks are the best way to drastically enhance floor performance and increase transversal rigidity. In an open-joist system, strongbacks can virtually eliminate vibration as they tie the floor together, giving it strength and stability.

It can happen that the stongbacks have to be cut to allow HVAC, plumbing and electrical passage. This is not a big issue. You can easily compensate by installing shorter strongback sections, attaching a minimum of three consecutive joists at a time.

For spans up to 16’, all you need is one perpendicular strongback running the entire length of the floor, installed at the center span. For larger spans, if two strongbacks are specified, simply install the second one adjacent to the next closest diagonal web bay, again towards the center of the span.

When installing smaller sections that are up against each other, it is preferable to overlap them with an additional splice member, as seen here.

A better floor assembly

Combining the above elements enhances your floor assembly’s structural integrity. It also increases its performance and assures its longevity.

Find out more about open joist TRIFORCE® by downloading our spec guide.