In North America residential construction, wood has long been a material of choice: abundant, readily available, flexible, and easily repairable, it is less expensive than steel and concrete, and is naturally an overwhelmingly popular material.

For some 40 years now, engineers and builders have had the choice between using traditional lumber or engineered wood for their construction. Now, in new residential buildings, more often than not, a combination of both is being used.

When it comes to floor systems, conventional wood has enjoyed a long tradition of use, created by a universal familiarity with the product as well as the amount of experienced, highly qualified workers using it.

Engineered Wood Floor Systems

Nowadays however, engineered wood floor systems are undergoing rapid market growth due to their many advantages over traditional wood. Engineered wood is more sustainable, using less trees and costs less to use per square foot. It weighs less and is easier to handle, saving time and money on construction sites. It is also stronger and more rigid in its support. Also, depending on the product you are using, you can easily adjust it on site, whether because of a deviation from the original plan or an adjustment to a non-conformity.

Types of Joists

Two types of engineered joists are most frequently used in floor systems today:

- Wood I-Joists with dimension lumber top and bottom chords and OSB web.

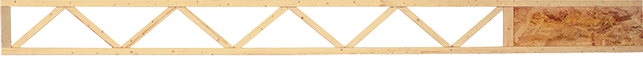

- Open web trusses with wood webbing held together with metal plates.

I-joists have major advantages in high-volume construction with standard layouts. This is because they are less expensive. Also, you can adjust their length is onsite, without an engineer’s approval. However, they can’t attain the spans of open web trusses. They are somewhat complex to run Mechanical, Engineering, and Plumbing through. This is due to the properties of the OSB paneling. There are some pre-defined hole locations but they are very small, and any additional holes to be made must follow strict guidelines so as not to compromise support.

Open Web Trusses

Open web trusses, on the other hand, have the advantage in more complex and more rugged construction. Their spans can be much longer than I-Joists. Open web design can accommodate almost any kind of HVAC, Electrical, and Plumbing configuration while allowing greater flexibility during installation. This is a time and money-saving characteristic.

They have specific lengths. You can’t trim them. This is their main disadvantage when on site. To adjust the open-web trusses’ length requires an engineer’s approval. Otherwise, it needs to be replaced. Either way, it requires an engineer’s seal. In both cases, this causes project delays. You need to add this to the open web trusses’ already higher cost.

Metal Connectors

One more thing: the metal connector plates used in this type of engineered wood joist are sharp. They can damage electrical wiring during installation. Pull the plate hard enough and some of its teeth can come out of the wood. This could compromise structural integrity. Also, trusses exposed to rain prior to the closing of the structure can rust. Sealants are available to coat the plates and make them waterproof. They require on site application.

A Hybrid Type

So, there are advantages and disadvantages to open-web trusses and I-joists but there is also a 3rd hybrid type of joist that is gaining in popularity, which effectively combines the advantages of both.

TRIFORCE® joists feature an open web design but do not use metal connector plates. TRIFORCE® is assembled with finger joinery and waterproof heat-rated adhesive.

You can adjust their length on site because of a trimmable OSB end panel. Joists are available in several depths and lengths and superior strength allows them to span up to 30 feet (TRIFORCE span tables). TRIFORCE® joists can fill the bill for any type of wood frame construction.

Open joist TRIFORCE® : A Compelling Engineered Wood Floor Alternative

TRIFORCE® costs less than open web trusses yet is as strong and as rigid. It has the added benefit of being adjustable onsite. This open joist TRIFORCE® is a compelling alternative in engineered wood floor systems, well worth investigating.

Open joist TRIFORCE® combines the advantages of other engineered joists to provide peace of mind underfoot.

My husband and I are currently in the process of having our new home built, and the contractors are using floor trusses to help build the structure. I was just curious on how this is beneficial to the building of our house. It’s good to know that this type of construction will help accommodate them when it’s time to put in the HVAC, electrical, and plumbing, which will probably make the process go quicker. That is something that will makes us happy, especially if there aren’t any snags along the way. Thanks for the insight!

Thank you for your comment Alex, Open web design is always preferable to I-joist type when it comes time to install the mechanicals. Much easier. Hope everything goes well for your new home!

Eric

It’s good to know that open web trusses can accommodate almost all HVAC, electrical, and plumbing configurations, making them a cost-efficient choice. My mom plans to have a new house constructed since she and Dad are divorcing in a couple of months. I’ll share this with her because I think prefabricated wood floor trusses would be an excellent choice for her new home. Thanks!

I was hoping someone could assist me in what floor joists to use.

I am building a log cabin. The dimension is 30×34 feet. Do mechanical trusses span 30 feet ?

Hello Alan,

Thank you for your intertest in TRIFORCE® open joist.

By downloading the TRIFORCE® Specifier Guide, you will find information that will assist you in the feasibility of using TRIFORCE® open joists on your project, including a Span Table.

Thanks for following us on this blog!

Should you need technical assistance, please call us.

The TRIFORCE® Team

1-800-263-7265

Have an addition I’m planning, 2nd floor over existing garage and fam room, 20×45. Due to the lack of support on the 20 foot span below I need to put wood I joist on the long span where now I will have outside and 2 interior support walls but one area of span will be just slightly too long for a traditional 2×10, but need to keep the floor height, is there a 9 1/2 ‘’ I joist that comes in a 45’ length

Hey Alan,

Are there s center interior bearing wall in the cabin picking center roof load? If it’s clear span a 30′-0″ truss 24″ deep, 24″ O.C. will work, I would use 2×6 lateral strong backs to take eliminate some deflection

Will be building in spring would like info on the triforsce beans

Do you know where I can buy from? I am building a house

Thanks

Hello Omer,

Thank you for your interest in TRIFORCE. For open joists pricing and stock availabilities, please contact one of our resellers by viewing the list here: https://www.openjoisttriforce.com/where-to-buy/

Best regards,

The TRIFORCE Team

If you put the eye joist on top of a two before wall and only have 1 inch to place the eye joist on the Two before wallis that enough support?

Hello Billy,

In this case, 1″ of bearing width on a bearing wall is insufficient. Minimum end bearing width for TRIFORCE® open web joists is 1-1/2″.

To have access to TRIFORCE Specifier Guide, please click here.

Thanks for reading our BLOG posts!

I love TriForce.

We are building an addition on our house. It is 17′ x 17′. It will be a kitchen. The basement will be a poured concrete floor with standard head clearance. What size of engineered floor joist do I need? Will I need a steel support post in the center?

Good day John and thank you for your inquiry!

TRIFORCE open joists will easily clear span 17′ under standard residential loading.

TRIFORCE span tables as well as installation instructions and details may be found in our Specifier Guide which can be accessed at the following link: https://www.openjoisttriforce.com/download-the-spec-guide/

Best regards,

The TRIFORCE team