Used for centuries in many different ways, cantilevers as a construction device were first recognized in 19th Century bridge designs. But they gained significant notice in architectural use when Frank Lloyd Wright unveiled his iconic “Fallingwater” commissioned residence. There the cantilever was not just a structural means to an end but also a dramatic design feature.

Today, cantilevers are commonly used for balconies and decks but are also effective in extending upper story living space beyond the boundaries of bearing walls. “Bargain” space results and architectural interest is often created through the use of cantilevers.

Let’s look at how best to frame for cantilevers when using an open web floor joist like TRIFORCE®.

Establish the Situation

Any time a cantilever is being considered as part of a floor system design, loading conditions related to the cantilever must be recognized and analyzed. Design software will dictate specific framing practices but for our purposes here, general approaches to cantilever installation will be discussed.

Cantilevers Parallel to Joist Direction

In this situation, while the open web joist stops at an exterior bearing, a 2X extension from it extends beyond the bearing to become the cantilever joist (see following illustration). This 2X is fastened to the side of a TRIFORCE® joist so that it “snugs” against the joist webs and under the top chord of the joist. 1-1/2” dimension lumber is attached to the top of this 2X so that the cantilever can achieve the same top plane as the open joist. Where this 2X crosses the bearing, a solid wood filler is needed to transfer load. If the cantilever is being extended from the trimmable I-Joist end of a TRIFORCE® joist, a 5/8” wood filler is required on the OSB panel.

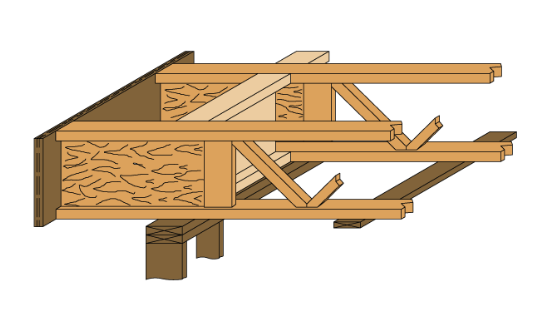

Cantilevers Perpendicular to Joist Direction

With TRIFORCE®, it is possible to construct a cantilever perpendicular to the joists by using 2X joists inserted through the open webs of the joists. In this situation, the following illustration shows proper framing to transfer load correctly to the bearing wall.

The recommended maximum extension for a cantilevered exterior deck is four feet. In this situation, 2X joists should extend back into the floor at least eight feet, using a recommended 2:3 ratio. It is possible to extend beyond four feet but each situation must be examined and analyzed for structural capacity.

In all cases where dimension lumber is used for framing an exterior deck, it is recommended that treated lumber be used.

For more information about framing cantilevers in a TRIFORCE® floor system, please download our spec guide. Contact us with any questions. We’ll be glad to help.

Closing in cantilevered joist spaces with solid blocking or panels above the supporting walls creates a cold cantilevered floor space. Insulating the cantilever is not enough to ensure a comfortable floor, air needs to move freely between the non-cantilevered joist spaces and the cantilevered joist spaces in order to maintain a comfortable floor above the cantilever.

Good day Kerry,

Our typical blocking detail, as illustrated in TRIFORCE specifier guide, can certainly facilitate this kind of situation.

Have a nice day,

Caroline

Wouldn’t a 4 foot cantilever and 8 foot backspan be a 1:2 ratio? Not 2:3.

Hello Karl,

Thanks for bringing up this question.

As per the detail above, 2 lengths units are devoted to be extended back into the floor while 1 length of this same unit is for the exterior deck, for a total of 3 units installed. This is why we say the 8 foot backspan represents a 2:3 ratio (2 on 3 units ratio) of the total 2X joist’s length installed.

Regards,

Caroline