For some time now, truss shops have turned to TRIFORCE® open joist for their floor system because they realize the many benefits of these open web joists. These shops build their own plated floor trusses however, partnering with TRIFORCE® has allowed them to save time and money, resulting in additional sales. Some or all joist-dedicated labor can be utilized on their roof trusses, thus increasing (and improving) trusses production.

This allows for more time on designing, manufacturing, delivery and installation. So, in the end, it’s the customer who gets better service.

Customers now have two options when it comes to an open web floor system. They can get aquote for TRIFORCE® joists and/or a conventional plated floor truss quote. By comparing the two, TRIFORCE® floor system will be more cost- effective along with a shorter lead time when quoting apples-to-apples against a conventional plated floor truss system. Inevitably, truss manufacturer’s quote/order win-ratio will improve.

By the same token, this partnership may help solve any labor shortage problems. This issue in the construction industry has been a significant concern in recent years. Addressing the labor shortage in construction requires a multi-faceted approach involving collaboration between industry stakeholders. Therefore, a partnership with TRIFORCE® is a very good solution.

Exploring the key benefits of TRIFORCE® for truss shop efficiency and sustainability:

1) Time efficiency & Quality assurance in floor systems

- Streamlining construction: Time-saving benefits of pre-assembled TRIFORCE®

Why TRIFORCE® helps save time for truss manufacturers. First, they arrive completely assembled, so all production time is avoided. - Quality assurance: TRIFORCE®‘s rigorous testing and reliable performance guarantee

Plus, all TRIFORCE® joists are individually tested and only proven joists are shipped to job sites. Because of this, builders know they can install TRIFORCE® joists with confidence and produce a floor system with performance backed by a lifetime warranty. - Precision and flexibility: how TRIFORCE®‘s trimmable design overcomes measurement challenges

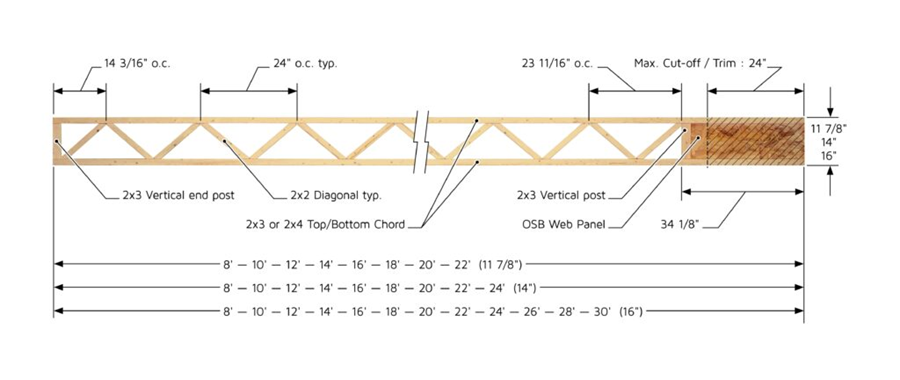

Measurement errors can occur with plated floor trusses. This will surely slow down the construction process. These issues will not happen with TRIFORCE® because they have a trimmable end. The length can be trimmed (up to 24’’) on site.

2) Discover the superior features of TRIFORCE® open joists: enhanced safety, efficiency, and installation ease

- Enhanced safety & installation ease with TRIFORCE®‘s metal-free

No metal plates. TRIFORCE® is all wood and uses finger-joint connections, so they are lighter in weight and safer in preventing stripped wires and nasty cuts to your fingers. - Optimizing floor systems: the Role of strongbacks in enhancing TRIFORCE® Performance

You may obtain a better performing floor system just by adding strongbacks at midspan. They are continuous horizontal members that attach perpendicularly to a series of open web joists within the floor cavity. Their purpose is to reduce vibration. In addition, they increase floor comfort and performance by limiting differential deflection. - Cost-effectiveness & easy Integration: How TRIFORCE® streamlines MEP installations

TRIFORCE® is a cost effective solution. With no metal plates and open webs, it allows contractors to quickly install plumbing, electrical and HVAC systems during or after construction which results in saving time. - Enhancing fire safety: TRIFORCE® joists’ compliance with IRC standards and superior fire resistance

Fire performance certifications: With the addition of a layer of gypsum board or wood cladding to their adjustable end, TRIFORCE® joists are compliant to IRC requirements for allowing exposed ceilings as with conventional wood joists. There are no metal plates that can buckle in the heat of a fire and potentially fail, such as with plated trusses. - Sustainability at its core: Eco-friendly advantages of TRIFORCE® wood joists

First, TRIFORCE® joists are all-wood construction, making them a good eco-friendly alternative. Wood is the most sustainable, natural and renewable building material available in North America, it is recyclable, reusable, and organic. Second, we worked hard to build a sustainable and green plant. Mostly made of wood, our manufacturing facility is 100% powered by hydro-electricity, a totally clean energy. To further minimize the ecological footprint, we made sure we use as little energy as possible to run our operations. So we can affirm that TRIFORCE® joists are a very green choice.

- Rapid production and supply: TRIFORCE®‘s automated facilities for timely demand fulfillment

TRIFORCE® open joists are mass produced and available within days. Knowing that mass-production is essential for continuous product availability, and because TRIFORCE® production facilities are fully automated, the factory can ramp up production quickly to meet demand. - Excellent after-sales service:

Questions are quickly answered and common repair details are available on our website.

3) TRIFORCE® offers three joist depths to accommodate builders

Such that: 11 -7/8’’, 14’’ and 16’’; leaving the truss shop to manufacture 18’’ deep and up. Please visit our website and download the Specifier Guide which will assist in choosing the best depth for your project.

If you are looking for an additional product offering as a means to increase sales and profits, look no further, TRIFORCE® open joist is your optimal choice.