“We shape our buildings; thereafter, they shape us.” Winston Churchill

We all know how challenging 2020 has been for everyone because of COVID-19’s massive impact it had on our industry. But once again, in spite of everything, our experts strove to bring you quality content and valuable information about technical challenges and new practices in construction, particularly around floor systems innovation.

Let’s take a look at the most popular articles of 2020, and make sure you haven’t missed anything!

#5 Construction trends for 2020

A very interesting overview of what we thought would be the biggest construction trends in 2020 Turns out we were spot on for most of it! From single-family homes sales rising to generational and design shifts in Millenials tastes, and greenification, sustainability, and efficiency being the center of attention in the construction industry, we had it covered.

Almost seems like TRIFORCE® being a greener and more efficient alternative to regular wood I-joist, that even helps builders save time and costs, was meant to meet the needs of modern construction!

#4 Why is TRIFORCE® advantageous over any regular wood I-joist?

When the time comes to choose between a regular wood I-joist or TRIFORCE® open joist, some characteristics of the latter are undeniably advantageous. To help you make a sound decision, we wrote this article comparing both. If you hesitate between TRIFORCE® and another truss solution, you can also read this article about choosing between TRIFORCE® and floor trusses.

In this article, we cover TRIFORCE®’s open web design and on the spot trimmable end, its fire-code compliance, and the minimal effort and cost required for an optimal vibration control. Plus, unlike I-joists, each and every one of our open joists is individually tested to meet even higher standards than those required by the model building code.

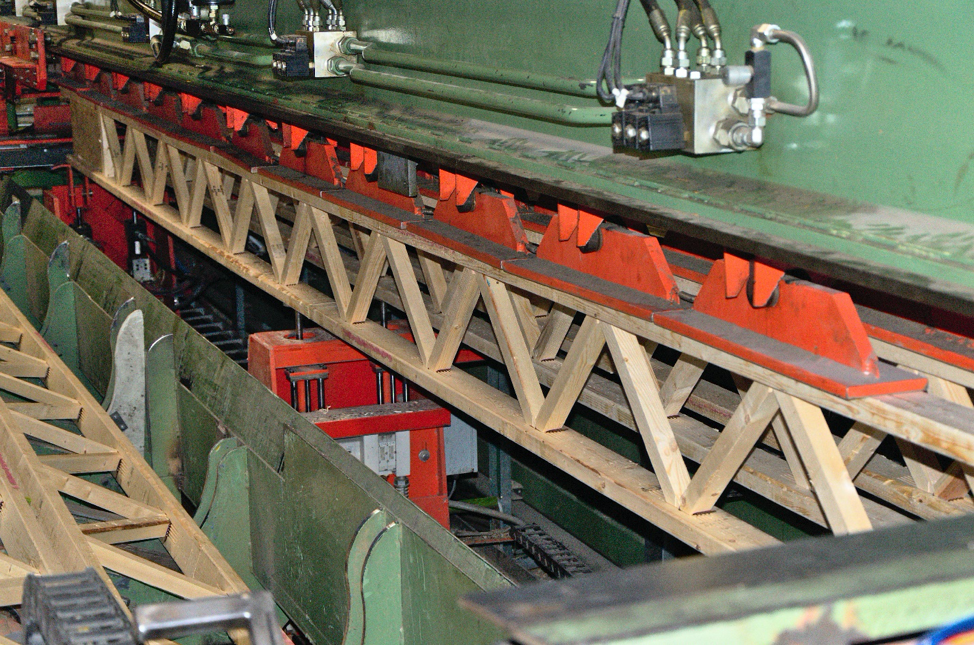

#3 Individually tested: only proven TRIFORCE® joists are shipped to job sites

Speaking about testing TRIFORCE® open joists, this article explaining a little more about our testing policy got quite the attention! Barrette Structural Distribution has an internal policy of testing each joist individually before it can be shipped to a construction site. Even though it is not required for code certification.

Discover more about how the TRIFORCE® is tested to ensure peace of mind to construction workers everywhere, and about Barrette’s lifetime product warranty.

#2 Advantages for builders to install strongbacks in an open web floor system

Even though strongbacks are not required in U.S. applications, they can help minimize the effects of vibration and significantly improve floor performance in all construction types. They are affordable and simple to install, especially in conjonction with open web floors.

Check out this article for more information about strongbacks installation and some useful tips to pair them effectively with an open joist floor system such as TRIFORCE®.

#1 A value-engineered next-generation open joist that saves you time and money

And finally, our most popular article of 2020. Comparing floor framing solutions is a subject that always seems to interest our readers, and with good reason. In this article, the yays and nays of steel-plated trusses, I-joists, dimensional lumber floor joists, and the TRIFORCE® open joist are discussed.

It should help you learn more about each option’s strengths and weaknesses and help you choose wisely which of those options fits your next project best.

Welcoming 2021 in the construction industry

2020 hasn’t been an easy year, to say the least, but it has brought us interesting construction trends that will most likely continue to impact the industry in the years to come, such as environmental concerns, availability of materials, and efficiency standards.

The TRIFORCE® open joist allows for more flexibility on the construction site, increased efficiency, cost reduction, and is as green as the raw material it’s made from. The wood is from the unused portion (the head) of local black spruce, using four times less energy than concrete and 60 times less than steel to produce.

Since it can be trimmed on-site, is always in-stock, and ready to be delivered in a matter of days, TRIFORCE® allows builders more confidence to move forward without delays.

For more information about construction news, trends, and technology, subscribe to our blog!