Public awareness about the fire safety of engineered wood floor joists has grown exponentially in the past 15 years. Tragic incidents involving rapid collapses of “I” beam type joists during residential fires shocked the public and fire authorities. Engineered wood joists weren’t fire-resistant. Later, the International Code Council established engineered wood fire performance requirements for one and two-story residential buildings. These are now in the International Residential Code.

The most recent version of these requirements is in section R302.13 of the 2015/2018 IRC. For those more familiar with the previous version of the residential code, it is the equivalent to section R501.3 of the 2012 IRC.

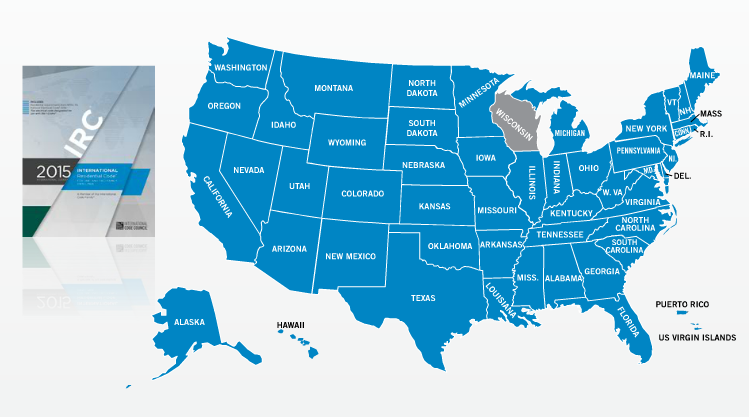

Currently, 49 states have adopted the International Residential Code.

Fire-resistant means being equivalent to 2 x 10

The fire-resistance benchmark for engineered wood joists is 2 x 10 nominal dimension lumber. This is a problem for I-joists in their natural state. This is because their entire central section is made of OSB paneling, which is a combination of wood chips and glue. It burns twice as fast as a 2 x 10.

Likewise, floor trusses or joists with steel frames have a similar problem. That’s because when exposed to the extreme heat of a fire, their metal plates become hot and eventually fall off the wood joist structure, allowing collapse.

The primary solution for engineered wood

The primary fix for these weaknesses is to install gypsum board on the underside of all framing to comply with fire-resistance standards. This isn’t an issue for a first-floor ceiling which will end up closed anyway.

A basement ceiling, however, is often used to run plumbing, HVAC and electricity. New home owners frequently prefer to leave the basement ceiling open. It costs less (no need to buy and install gypsum board) and it allows them access for mechanicals maintenance. Also, opening the gypsum makes it vulnerable to fire. Never the less, gypsum ceilings remain the most commonly used solution.

Alternative fire performance solutions

Because not everyone wants to install gypsum board, fire resistance can be ensured in other ways.

- In some areas, sprinklers are mandatory

- Mineral wool batts that rest on the bottom chords of the joists

- Ceramic blankets stapled to the joists

- Factory installed protection

- Fire-resistant suspended ceilings

- Cement-based panels attached directly to the floor membrane

The TRIFORCE® fire performance solution

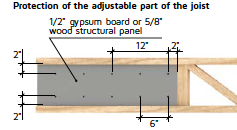

Sometimes, the simplest solutions are the best. For example, open joist TRIFORCE® is made almost entirely of natural wood, precisely assembled using fire-resistant structural glue. It complies with section R302.13. of the 2015 IRC. All that required is the addition of 1/2″ gypsum or 5/8″ structural panel to each side of the OSB on the joist’s adjustable end.

Therefore, with TRIFORCE®, there is no need to install a gypsum board ceiling or other alternative solutions for the floor system to be fire-resistant.

Furthermore, TRIFORCE® has no spray-on coating that can contain formaldehyde.

Finally, the TRIFORCE® joist has an open web design allowing maximum freedom when installing mechanicals.

Learn more

Learn more about how this exceptional product and how it can help you comply with the latest fire regulations without any additional costs or effort. Download our fire-resistant solutions guide!