Let’s take a look at some TRIFORCE® projects with illustrations. See how to properly fasten your TRIFORCE® joists with hangers. We are going to examine some real-life cases of engineered wood floor joist structures. Take a closer look at the joists installation and other details that help you visualize how the floor is supported. These pictures show that TRIFORCE® is a high-quality product which results in a seamless and stress-free construction experience.

1) Hanger support:

We see here a residential construction. This picture shows a TRIFORCE® joist assembly supported by hangers on a laminated beam. As the span of this single-ply beam was too long, a column has been added for support. This picture also shows the space available for installation of all types of MEP, which is an excellent advantage of TRIFORCE® joists.

2) 2 types of joist attachment

Here is an example of two different types of support, on one side, joists are supported by hangers and on the other side, the joists are bearing on a wall. On this section (right side), we can also see the OSB rim joist. It’s another case of a residential construction with wood to wood connections but another advantage of TRIFORCE® is that it’s also easily possible to do wood to steel connections.

Whether for steel, concrete or engineered wood structures, architects today are taking advantage of the different characteristics of each material to combine them in unique designs. As we see more and more use of steel beams in residential construction combined with engineered wood floor structures, fortunately, it’s possible to make these materials work together. When it comes to wood to steel connections with open joist made entirely of wood, the two connection options most commonly offered to builders are:

Steel beam connections with hangers:

Steel beam connections without hangers:

Because these two materials have different properties, an important factor to consider is the quality of the connections when it comes to combining wood and steel.

The behavior of a steel-wood connection can change over time, due to various factors such as load, humidity, temperature variations, etc. For example, wood can contract or expand depending on humidity levels. Steel, for its part, can be subject to corrosion over time, which can affect the overall behavior of the beam.

Joists supported by a bearing wall.

In the picture above, we see the rim joist closer, acting as a bracing element. The rim board is generally perpendicular to the joists and responsible for transferring vertical loads. The top plate of the wall above and subfloor are fastened to the rim board, and the rim board is fastened to the joists and the doubled top plate of the loadbearing wall below. This assembly adequately transfers loads down to the foundation.

A beam supporting joists on both sides

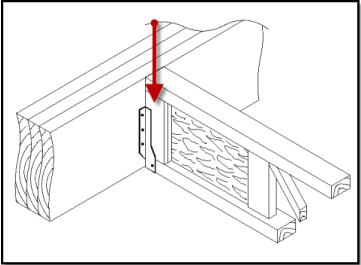

A hanger must also hold the supported member laterally. If using face mount hangers that do not reach and restrain the top flange of the supported joists, “wood Filler” blocks should be installed between the top and bottom flanges to fill the gap, as illustrated below.

Example:

It is recommended that the height of the face mount hangers be at least 60% of the height of the supported members. See here a proper installation:

3) Stairwell under construction

The picture shows a standard residential stairwell. Staircase loads must always be taken into account in the calculations of an open joist system. Design challenges include not only loads, but also the type of staircase, whether it changes direction or has a rounded shape. Often the girder joist bordering the stairwell must be doubled to carry the supported member. The Analyzer software may be used to make this determination. We make this software available for download on our website. It’s efficient and user friendly, which makes calculations easier.

Learn more about TRIFORCE® and how this revolutionary product can simplify your construction by downloading our specguide.