Have you ever taken part in a conversation that involved cutting holes in I-joists? Was it because an improper cut called for a repair? Or was it a communications issue between subcontractors as to the exact placement of the holes?

Did you find yourself wishing there was an easier way to just get on with the work?

Some manufacturers will recommend that the placement of the holes be worked out in the design phase. Practical experience, however, teaches us that subcontractors such as plumbers, electricians, and HVAC installers would rather “take charge” of that aspect of the work themselves and decide optimal duct and piping paths in the “real world”. They arrive after the structure is up, so are plans absolutely essential to their work? You have to admit that by the time they get to the site, there may have been deviations to the plan and following them would just be a waste of time.

This kind of logic doesn’t help the GC though. Because if each contractor acts according to their judgment, it greatly increases the chances of having improper cuts that can weaken the joist.

limitations when cutting holes in joists

Anyone who’s followed joist manufacturers’ instructions as to where and how to make will tell you there are a lot of things to watch out for:

- Minimum distances from the ends and the top and bottom of the joists

- Minimum distances between holes

- Maximum sizes of holes

- You have to be careful not to overcut the corners of square holes

- Of course, flanges are to be completely avoided: no cutting or notching. This is basic logic and goes for all joists. The amount of compression and tension these upper and lower members are designed to handle makes them dangerous to cut.

Furthermore, climbing up and down a ladder and drilling at an uncomfortable angle, careful to make a straight line of holes across a row of 10 or 15 joists, is kind of a hassle too.

Also, doesn’t repeatedly cutting holes into freshly installed joists feel kind of counterintuitive?

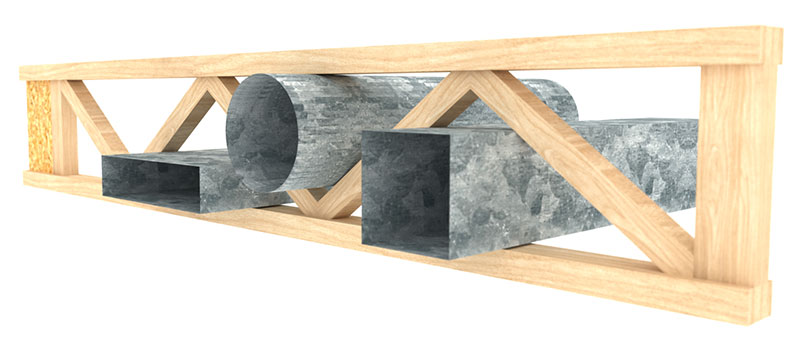

Ok, maybe I’m getting over the top. Here’s my point. The open joist concept eliminates all of these tedious considerations.

- Eliminates all the hole-drilling and drastically speeds up the plumbing, electrical and HVAC installation.

- Allows subcontractors to move ducts and piping across the floor structure much more freely.

- It provides peace of mind to the GC knowing that the work of the previous subcontractor won’t interfere with the next one’s job.

It’s a simple, elegant solution to problems that shouldn’t even exist.

That said, we think you should give TRIFORCE® open joist a try. Or, talk to one of our distributors and ask them about our satisfied customers. You can also download our spec guide or contact us.

We’ll be happy to free your mind from the worries of joist web hole drilling.