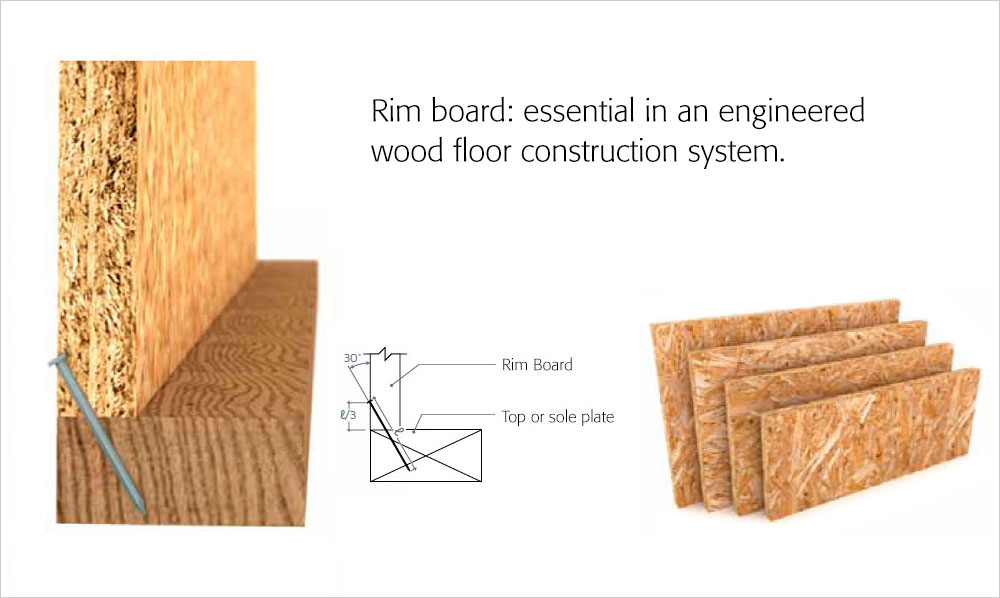

However simple the rim board may seem, it is a central element in an engineered wood floor construction system.

It literally carries the load: Installed perpendicular or parallel along the outside of TRIFORCE® open-joist floor structures, the rim board carries axial and lateral loads from the exterior wall and also helps resist lateral shear loads from floor sheathing and inside walls, to ensure load transfer between levels of a structure and improve the structure’s quality.

A few tips for choosing the right rim board: Avoid Sawn lumber, which usually has higher moisture content than engineered wood. As it dries, sawn lumber can shrink significantly, reducing its participation in the load transfer and leaving the load from the upper floors and roof to the TRIFORCE® structure with potentially disastrous results. Choosing an EWP floor system (joist) creates lots of potential for the construction design (ex: greater span) and EWP rim board should be used to ensure the assembly’s quality and dimensional consistency.

APA rated rim board is your optimal choice: It is easy to install, offers a smooth consistent nailing surface, contains no core voids and won’t delaminate. It will also provide the tight fit that is essential for proper load transfer to the level below.

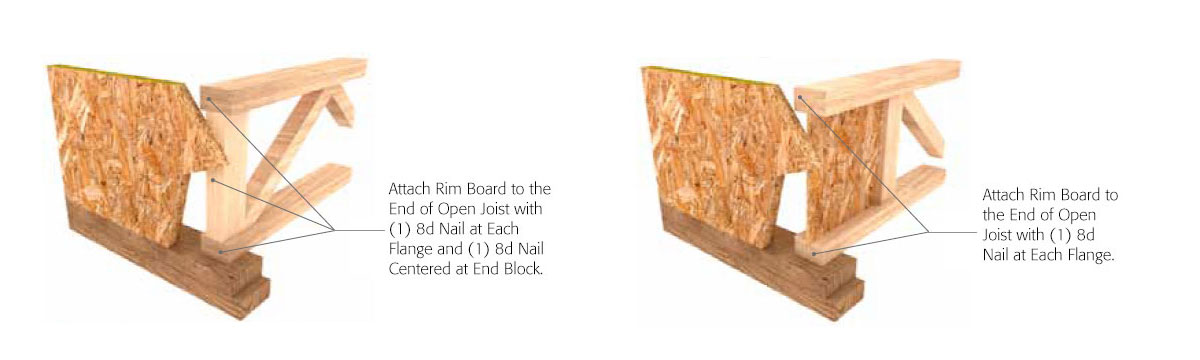

Installation is pretty simple, as shown here:

It’s also important to note that when using the TRIFORCE® floor joist system, we do not recommend using TRIFORCE® open-joist floor joists as solo starter joists on exterior walls. Only TRIFORCE® EWP rim boards have the appropriate strength for this type load transfer.

However unassuming it may seem, the EWP rim board is an essential element for your project that will ensure maximum quality for your floor structure.

To see more on how to install the rim board, download our installation guide.