TRIFORCE® experts are regularly invited as speakers for continuing education webinars. One participant recently asked if open web floor joists still require rim board. I thought that was an interesting question because once you understand everything rim board does, you adopt it.

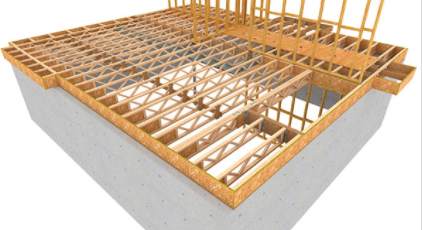

Rim board: An essential part of an engineered wood floor system

Rim board sits on the sill plate and forms a band around the perimeter of an engineered wood floor system, matching the full depth of the joists. Thanks to its connections to the floor membrane, sill plate, and joists, it transfers vertical and lateral loads. This way, it helps the floor system act as a unit.

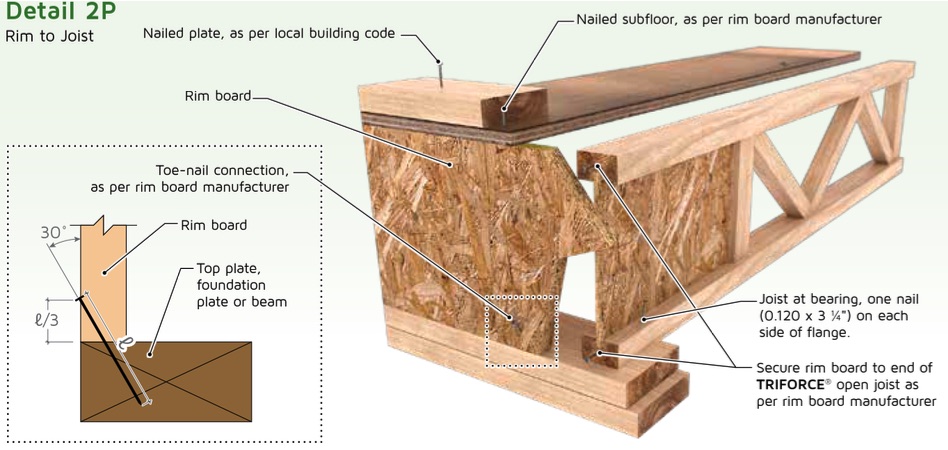

How to connect the rim board

Here is a rundown of how to connect the rim board. This is in compliance with construction standards (ICC’s Acceptance criteria for rim board products (AC124), APA and Codes).

Floor diaphragm (subfloor) connection

Boundary nailing attaches the floor diaphragm to the rim board. This helps transfer in-plane lateral loads from the floor diaphragm through to the sill plate and into the foundation.

Joist connection

Connecting the rim board to the joists provides lateral support to the joists and resistance against rotation. For example, in storm or high wind conditions, rim board will help distribute horizontal loads more evenly to resist shear and transmit shear loads to the sill plate, or along the axis of the joists. To connect the rim board to the TRIFORCE® joist, use one nail for each flange.

Sill plate connection

Along with the above mention functions, the rim board’s connection to the sill plate helps it carry vertical load, of course. This continuous connection plays an important part in ensuring load transfer between floors of the structure. Nailing (toe nailing in this case) should be at a 30-degree angle.

Recommended rim board materials

There are different types of materials available for the job, such structural rim board, plywood and OSB. We recommend APA rated minimum 1″ structural rim board. It has a smooth consistent nailing surface, a very uniform core and won’t delaminate.

Finally, whatever materials you use, it is essential to have a tight fit for proper load transfer.

So, to the question “do open web floor joists require rim board?”, I would have to answer an enthusiastic “yes”!

To have access to more technical details, download our TRIFORCE® Spec Guide!

You don’t clearly answer your question: “does an open web floor joist require a rim board?” You do say “. . . . an essential part. . . .” But no explanation of why. Code says all products must be used as per manufacturer’s specs. What’s the reason it’s required?

thank you,

Paul DeBaggis, CBO

Franklin, Mass.

Hello Paul,

To the question “does an open web floor joist require rim board?”, we would have to answer an enthusiastic “yes”! Why?

Thanks to its connections to the floor membrane, sill plate, and joists, rim board transfers vertical and lateral loads. In other words, this helps transfer in-plane lateral loads from the floor diaphragm through to the sill plate and into the foundation. This way, it helps the floor system act as a unit!

Best regards,

Caroline

I installed fire rated Triforce joists in a custom home I am currently building. Do we have to cover the trimmable ends to make them fire rated as well? I’m trying to make the change from 2”x Yp but covering the trimmable ends is a lot of extra work. Thanks Doug

Hello Doug,

TRIFORCE® open joist has been evaluated for equivalent fire-resistant construction to dimensional lumber or structural composite lumber equal to or greater than 2-inch by 10-inch nominal dimension, in accordance with Exception 4 of Section R302.13 of the 2015/2018 International Residential Code® (IRC). In this case, TRIFORCE® open joist to be clad with minimum 1/2” unrated gypsum board or 19/32” wood structural panel fully covering both faces of the 3/8” OSB end panel fastened with 1” nails or screws at 6” o.c. with 2” edge spacing. Gauge staples may be substituted for nails or screws. Download all details here:

This is the fastest and easiest way to enjoy the benefits of a high quality engineered floor system without costs additions such as drywall ceilings or sprinkler systems.

Thanks for using TRIFORCE in your floor system!

Caroline

A house that I am currently bidding a job for to replace the deck I noticed that the ledger (2×10 pressure treated) for the deck had been bolted with lags to the??? Wait there’s no band joist on the back of the house! They used half inch osb and spanned it to the sill plate. Is this legal?

P.s. it’s in doylestown pa